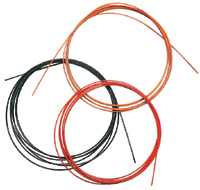

Color-coding identifies the ID of your 1/16" OD PEEK tubing – each ID is coded with a different color.

PEEK tubing has the strength required to withstand continuous use at HPLC pressure without swelling or bursting, and is not affected by halide salts, high strength buffers, or other aggressive mobile phases that corrode stainless steel. The polymer surface will not leach metal ions into the eluent or extract metal-sensitive components from the sample. Note however that dichloromethane, THF, and DMSO may cause swelling in PEEK, and concentrated nitric and sulphuric acid will attack PEEK.

Tolerance is ±.0005" for IDs up to .010", and ±.001" for larger IDs.

| Tubing ID | Color | Tolerance | Bar* | Psi* | Product No. |

|---|---|---|---|---|---|

| .004" | Black | ±.0005" | 460 | 6700 | JR-T-5804 |

| .005" | Red | ±.0005" | 460 | 6700 | JR-T-6007 |

| .007" | Yellow | ±.0005" | 440 | 6400 | JR-T-6008 |

| .010" | Blue | ±.001" | 420 | 6100 | JR-T-6009 |

| .020" | Orange | ±.001" | 345 | 5000 | JR-T-6010 |

| .030" | Green | ±.001" | 262 | 3800 | JR-T-6011 |

* Recommended maximum permanent working pressures calculated

from the burst pressure and the factor 2.5