World's first True Nano™ UHPLC!

The integrated nanopump/injector comprises an entire chromatographic system in a small footprint weighing a few pounds. With true nanoscale 360 µm fittings and extremely low flow rates, this system provides split-free injections as close to the detector as possible.

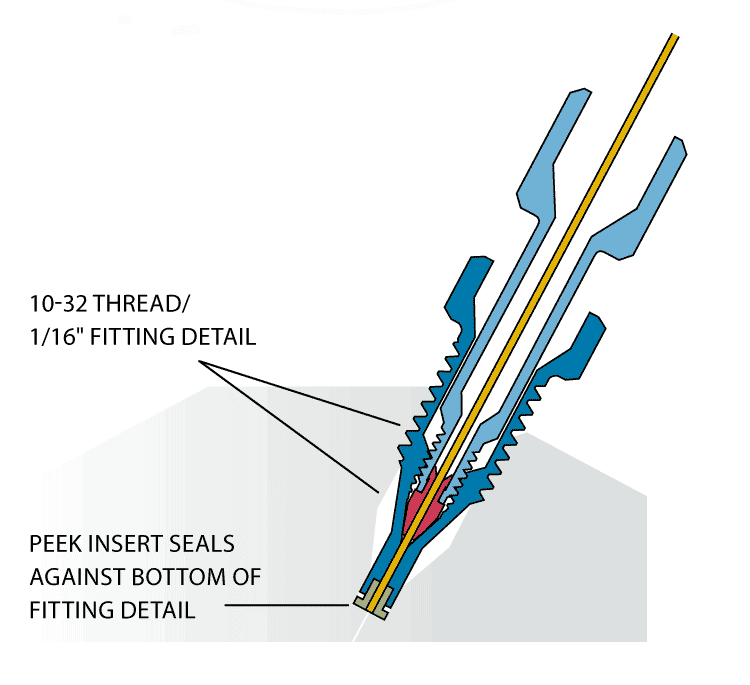

360 µm tube to 1/16" fitting

Our new fitting connects a 360 µm FS tube directly into a 1/16" fitting detail, with the bore of the FS tube precisely aligning with the bore of the valve.

Fused silica prep kit

Typical methods of cutting fused silica leave a burr. This kit includes everything needed for a simple lapping procedure which polishes the burred end into a clean, perfectly square-cut surface.

10K-20K psi injectors and selectors

Cheminert UHPLC injectors, switching valves, and selectors with 360 micron, 1/32", or 1/16" fittings make it easy to minimize internal volume and eliminate dead volume. Ideal for high speed, high throughput nano flow LC techniques.

UHPLC Fittings

Valco fittings are available for 1/32", 1/16", and 1/8" tubing.

Our Cheminert Nanovolume® fittings are designed for direct connection (no liners required) of 360 micron tubing.

Tubing

Stainless tubing is available in 1/32", 1/16", and 1/8" OD, in pre-cut or custom lengths.

Electro-formed nickel tubing is available in 360 micron, 1/32", and 1/16" ODs, and a range of IDs and lengths.

40,000 psi ultra-high pressure injector system

The VICI 40K UHPLC injector is comprised of six miniature air actuated needle valves, plumbed to simulate the flowpath of a conventional rotor/stator injector.